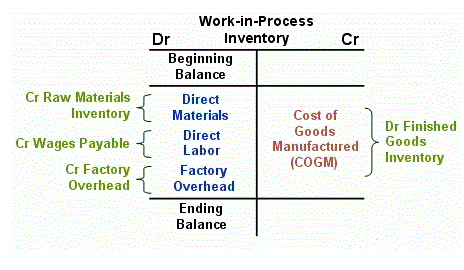

Therefore, once the batch of sticks gets to the second process—the packaging department—it already has costs attached to it. In other words, the packaging department receives both the Restaurant Cash Flow Management drumsticks and their related costs from the shaping department. For the basic size 5A stick, the packaging department adds material at the beginning of the process. The 5A uses only packaging sleeves as its direct material, while other types may also include nylon, felt, and/or the ingredients for the proprietary handgrip. Direct labor and manufacturing overhead are used to test, weigh, and sound-match the drumsticks into pairs. It is the direct labor plus any manufacturing overheads needed to convert raw materials into a finished product.

The manufacturing sector analyses both prime costs and conversion costs to measure efficiency in the production of a product. In the Peep-making process, the direct materials of sugar, corn syrup, gelatin, color, and packaging materials are added at the beginning of steps 1, 2, and 5. While the fully automated production does not need direct labor, it does need indirect labor in each step to ensure the machines are operating properly and to perform inspections (step 4). Thus, conversion costs are all manufacturing retained earnings balance sheet costs except for the cost of raw materials.

Thomas J Catalano is a CFP and Registered Investment Adviser with the state of South Carolina, where he launched his own financial advisory firm in 2018. Thomas’ experience gives him expertise in a variety of areas including investments, retirement, insurance, and financial planning.

Conversion costs are also used as a way to measure the efficiencies in the production processes but they also take into account the overheads in the production process, which are not calculated in prime costs. Consider a professional furniture maker who is hired to make a coffee table for a customer. The prime costs for creating the table include the cost of the furniture maker’s labor and the raw materials required to construct the table, including the lumber, hardware, and paint. It is easier to track the conversion costs materials and conversion costs for one batch and have those costs follow the batch to the next process.

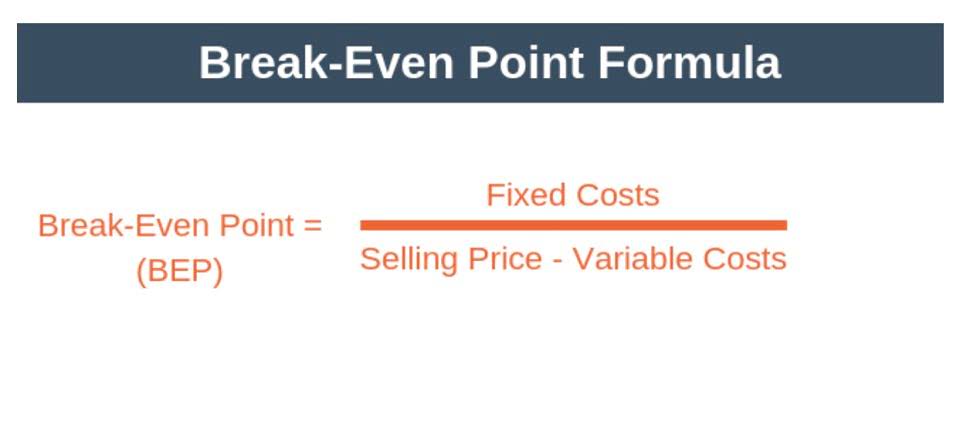

Therefore, the conversion cost per unit for the month was $6.80 per unit (calculated as $136,000 of total conversion costs divided by the 20,000 units produced). The calculation for prime costs includes the amounts spent on direct materials and direct labor. Tangible components—such as raw materials—that are needed to create a finished product are included in direct materials. Hence, using conversion costs is an efficient way of calculating equivalent units and per unit costs rather than separately calculating direct labor and manufacturing overheads. Prime costs and conversion costs are relied upon heavily in the manufacturing sector to measure efficiency in the production of a product. Prime costs are expenditures directly related to creating finished products, while conversion costs are expenses incurred when turning raw materials into a product.

11 de marzo de 2021

Publicado en: Bookkeeping